Alloy Nipples and HM Washers – A Good Idea?

Nipples are the little screw that hold the spoke into the rim on the wheel. While they may seem  like an entirely straightforward selection for your wheels, there is quite a bit more detail to them than you might imagine. Quality nipples come in two major materials. Either brass or aluminium alloy. Manufacturers of spokes such as Sapim, Wheelsmith, DT, Alpina all provide nipples with their spokes and in the overwhelming majority of cases you get some sort of nickel coated brass nipples. These are cheap to manufacture and resist corrosion.

like an entirely straightforward selection for your wheels, there is quite a bit more detail to them than you might imagine. Quality nipples come in two major materials. Either brass or aluminium alloy. Manufacturers of spokes such as Sapim, Wheelsmith, DT, Alpina all provide nipples with their spokes and in the overwhelming majority of cases you get some sort of nickel coated brass nipples. These are cheap to manufacture and resist corrosion.

Sapim Alloy Nipples

The main benefits of alloy nipples are weight saving. However, commonly these are made of the 2000 series aluminium which are comparatively weak. They can deform during the build, they can corrode with the elements and seize up to prevent re-truing. In contrast, Sapim’s alloy nipples are made out of 7075 aluminium which is stronger and more fatigue resistent. It also has a special anodized coating which resists corrosion. A problem that has plagued alloy nipples in the past.

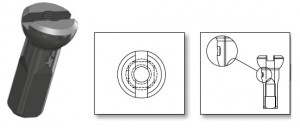

For the vast majority of our builds we use Sapim ‘double square’ nipples, which have numerous advantages over their more traditional slotted counterparts. They have longer threaded sections which means more threads on the spoke can engage, spreading the load better. They can be adjusted with a square driver as well as a conventional spoke key which reduces the chance of the colourful anodising and protective coating being damaged during building or truing. However the main advantage is the increased strength when compared to nipples of a slotted design – which can collapse in at the top if the spoke doesn’t reach the very top of the nipple. The double square nipples to not have a weak point like this and therefor are not vulnerable to the same types of failures sometimes seen with slotted nipples.

which have numerous advantages over their more traditional slotted counterparts. They have longer threaded sections which means more threads on the spoke can engage, spreading the load better. They can be adjusted with a square driver as well as a conventional spoke key which reduces the chance of the colourful anodising and protective coating being damaged during building or truing. However the main advantage is the increased strength when compared to nipples of a slotted design – which can collapse in at the top if the spoke doesn’t reach the very top of the nipple. The double square nipples to not have a weak point like this and therefor are not vulnerable to the same types of failures sometimes seen with slotted nipples.

The new coating also means that these nipples require less lubrication – although we still recommend builders lubricate all nipples, with the exception of spokes under low tension – for example the on non drive side rear. They are squeal free during the build. They also retain the weight saving advantages over brass. Sapim are confident that their alloy nipples will actually out-last their brass versions as they held up better to salt water tests. Alloy nipples can also come in different colours if you wish; green, gold, purple, black, blue, red and silver.

A few years ago now Sapim released a type of nipple called SILS, that contained Sapim’s Integrated  Locking System. This system prevented spokes from loosening by deliberately imperfecting the thread in a certain way. They are only recommended for use with Sapim spokes and experience tells me that they do not work with DT Swiss for example. If you are planning to use them for a build, it is worth keeping an eye on the wind of the spoke. The increase friction can damage the spoke unless extra care is taken; this is a particular problem with the Laser spoke.

Locking System. This system prevented spokes from loosening by deliberately imperfecting the thread in a certain way. They are only recommended for use with Sapim spokes and experience tells me that they do not work with DT Swiss for example. If you are planning to use them for a build, it is worth keeping an eye on the wind of the spoke. The increase friction can damage the spoke unless extra care is taken; this is a particular problem with the Laser spoke.

Nevertheless loosening is a problem worth trying to overcome. Even high end wheels can work loose leading to a potentially dangerous wheel. Different builders and manufacturers use different approaches to tackle this. Some use no lubricant at all during the build to maximise friction however this can cause damage to the components during the build and inhibits the high tensions required for a stiff wheel. It also can cause the spoke to seize up, preventing retruing. Others, like myself, use linseed oil as an organic substance that lubricates during the build but then acts like a mild threadlock afterwards. This is what I use on wheels that do not use locking nipples. You can use light thread locking compounds (like DT’s spoke freeze) in conjunction with other lubricants to retain some re-truing potential.

SILS nipples have recently been superceeded by secure lock nipples. The technology is similar but the nipple is slightly different. Previous SILS nipples became stiff when screwed further onto the spoke. These have tight spots and slack spots. Secure lock nipples can be identified from other nipples because of the depression on their side (not visible when built). Sapim say that lubrication is not required when using their alloy nipples, however I do still recommend it. It helps to prevent corrosion even further and helps to prevent wind up on builds. I also recommend the use of a Sapim or DT Swiss spoke key for use with all Sapim nipples, they are available through DCR for £17 and include free delivery (UK).

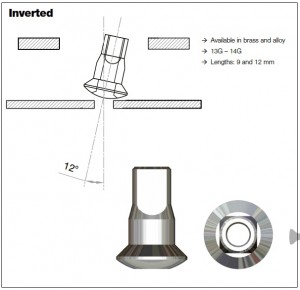

Secure lock nipples are also available in an upside down or inverted version. This does differ  from turning an existing nipple upside down; it does not have a groove for a nipple driver. This is a key difference because that groove will eat into your rim and cause unnecessary friction during the build. Inverted nipples have become more popular on carbon aero rims because the nipple interrupts the aerodynamics of the wheelset.

from turning an existing nipple upside down; it does not have a groove for a nipple driver. This is a key difference because that groove will eat into your rim and cause unnecessary friction during the build. Inverted nipples have become more popular on carbon aero rims because the nipple interrupts the aerodynamics of the wheelset.

Another recent addition to the Sapim range is the HM nipple washer. This has been designed for use with non-eyeleted rims. Sapim maintain it is better to use a washer on a non-eyeleted rim, it provides a better surface to contact with, reduces friction, spreads the load better and helps to resist corrosion. However, it will add weight to your build and may require you to use longer spokes. The majority of our builds do not contain washers, but get in touch if you have queries.

Brass or aluminium?

If brass is stronger, why go with anything else, you might ask? Well the question asked of every component on a bike is really is it strong enough? Brass nipples are roughly 3x heavier – across a 32h wheelset this adds up to 58g. If you’re thinking that doesn’t sound like much, imagine that weight saving was offered in a hub for no extra cost – most people would take it. It is a valuable upgrade because it does not come with any disadvantages. Alloy nipples make sense as an upgrade if you are looking to add colour or performance to your wheelset.

Weight of 1 nickel coated brass nipple (18mm double square) – ~1.3g

Weight of 1 alloy nipple (18mm double square) – ~0.4g

Weight of 1 HM nipple washer – ~0.17g

Thickness of 1 HM nipple washer – ~0.7mm

If you were to add HM washers to a pair of 32 spoke wheels you will add approximately 11g to the wheelset. If you were to add them to a 20:24 laced wheelset you would add approximately 7.5g. When calculating spoke length if you are using HM washers, it is best to add 1.5mm to your effective rim diameter.

There is a lot more information available about choosing wheelsets, building wheels and selecting component parts as well as information on repairing wheels in Bicycle Wheelbuilding: The Manual an ebook which is available to purchase exclusively here:

https://dcrwheels.co.uk/products-page/product-category/bicycle-wheelbuilding-the-manual/