Alto Wheelsets

Alto Wheelsets

We have created a separate section for Alto Wheelsets here because it is unusual for us to sell components specifically designed to be run together. The hubs and rims can be run separately in ‘hybrid Alto’ sets or as complete sets as ‘Full Alto’ sets. Hybrid sets can be a way of changing the sets characteristically but generally are used to provide Alto components more economically.

All Alto components come with a 5 year warranty and a 40% crash replacement scheme. None of them have any rider weight limit and meet the highest possible manufacturing standards, providing the best possible performance and longevity.

If you want to read only about Alto carbon rims, you can jump to that here.

Alto road hubs

- Front – 83g

- Rear – 249g

- 576pt freehub engagement

- Bearings – 6802/6902

- R-Symmetric design (improves lateral and torsional stiffness)

- One piece axles

- Made in the USA

- Wide bracing angle.

DCR says:

These hubs were designed to provide exceptionally fast freehub engagement, high lateral stiffness and fantastic rolling resistance even in real world conditions. Some hubs feel fast in your hand but not out on the road and certainly not on the bends. Alto are different, decent sized bearings, angular contact design, 15mm axles, careful bearing placement means that the bearings themselves can run well when being subjected to both vertical and lateral loading.

The R-Symmetric design does three key thing things, it shortens the spoke length, allows a radial pattern and it increase the bracing angle. High-low designs are not unusual, but one that is this high are very unusual. The high flange essentially acts as if the spoke is initially traveling vertically, then dives in towards the rim. Having the option of running radial lacing also increases stiffness, it has always been the stiffest pattern, a shorter spoke has less spoke stretch and being able to lace radially with heads in is remarkable, it really does deliver the widest angle you can achieve in a hub. Wider angles improve comfort as well as stiffness. The front is a wide angled front as well to accompany this rear.

Freehub engagement is a fixation that many people have on the trails, but not so often on the road. It nevertheless provides an appreciable real world difference. It makes the power delivery feel more immediate.

You can feel that these hubs are made with the precision that Alto are proud of. The weight of the set of hubs is not chart topping, however you can see that the split is disproportionate front/rear. The rear is where the extra weight as and that weight is in that drive side flange. Weight in a wheelset is best carried in the hubs and given the other features the design offers, it should not be a concern for a rider looking to lay down power.

You can read more about how Alto hubs compare with other high end hubs here.

Alto disc hubs

Alto say:

Alto hubs are made in the USA and offer the absolute best performance and durability of any hub on the market, period. Our patented R-Symmetric design and bearing closure system, coupled with genuine NSK bearings, will save you precious watts and provide the smoothest ride quality you’ve ever felt!

Borrowing from the success of the Alto rim brake hubs, they now have a range of disc brake hubs as well which are available in a range of colours and axle interfaces. They also now offer Boost hubs as well.

The weights for their hubs are as follows:

Front disc – 115g

Rear disc – 271g

Front Boost – 125g

Rear Boost – 281g

Each can be provided with Shimano, Campagnolo and Sram XD freehubs.

Alto rims

We only offer Alto’s carbon rims. For an Alto hubbed alloy wheelset, we recommend selecting the Aforce Al33, a high end, aero, tubeless compatible rim which can be built up with internal or external nipples.

Alto carbon rim brake road rims are:

- EPS molded system

- Filament wound

- UCI approved

- Modern wide aerodynamic profiles

- Proprietary layup

- Ultra high temperature resins

- 3d angled spoke holes

- Semi-UD finish

- Designed for 25c tyres

- 40mm, 52mm and 86mm depth

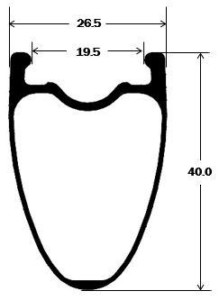

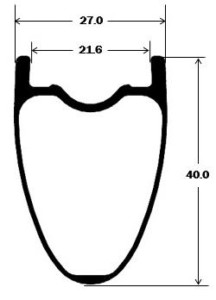

Alto CC40

The CC40 is the lightest rim brake rim in their range. Not a ‘climbing’ rim; partly because it is still 40mm deep and partly because it is 480g. It is the rim in their range which could be used in the broadest range of applications. It is the most stable on windy days yet provides a greater aero benefit than any aluminium rim.

is the lightest rim brake rim in their range. Not a ‘climbing’ rim; partly because it is still 40mm deep and partly because it is 480g. It is the rim in their range which could be used in the broadest range of applications. It is the most stable on windy days yet provides a greater aero benefit than any aluminium rim.

Alto are particular with their carbon layup because they know the difference it makes. They have a different front/rear layup and a different layup for the drive side and non-drive side. They have completely different layup systems and different carbon and resin for their disc brake rims.

Alto do this to produce some of the most sophisticated composite rims available. They are tubeless compatible. They are best suited to 25c tyres but can be run with other widths. They are wide and slightly pointy profiles that produce lower drag with wider tyres and also delivery high levels of comfort and stability.

Alto have done a heat resistance comparison test for their rims verses a number of alternatives which you can view here.

Alto have always worked hard to eliminate the issue of heat failure on carbon. Despite being our ‘go to’ carbon rim for even the largest of riders on carbon and recommending them for all conditions. Since transitioning to filament winding, their rims now provide even great heat resistance. I am going to resist the temptation to wade in too deep with what the results of this test do show. The intention of this test was to take the rims to their limits – how close you would get to those limits in real life is not something Alto are trying to advise here. They are not trying to say that other manufacturers wheels are unsafe, but the results are interesting nevertheless. From my perspective, points of interest are:

- Alto were the only rims to progress to phase 2 of testing which they still saw no issue with. The extent to which Alto out-performed rims in this test is stark as well. We are not talking about a few percent here, we are talking about all other rims being destroyed fairly rapidly and Alto withstanding the temperature indefinitely. I feel I should also point out that this is the sort of internal testing rig that rim manufacturers would use when developing their rims to see how heat spikes and at what point their rims would fail. A failure against this sort of test is absolutely commonplace. So the Alto result is certainly remarkable.

- What the results show that is also quite interesting is how rims handle prolonged heat exposure. A lot of rims can handle a heat spike; it is generally prolonged braking, even with comparatively little force which seems to present issues with temperature. It is why Alto’s recovery time is important but also why the duration they can tolerate temperature for is important. Rims which handle heat better and keep within their comfort zone during braking will last longer as well as keep you safer.

- ENVE rims performed best out of the rest despite ENVE’s insistence that the Swissstop Black Prince pads not be used with their rims. I think that demonstrates how resilient ENVE have now made their rims and we have seen no issues with their NBT either with their pads. Nevertheless, in the test, the ENVE rims were still a long way from Alto.

- I think that the performance of the Knight rims is particularly disappointing here. They are a high end rim, they reportedly use one of the highest temperature tolerant resins, they too use a modern, sophisticated, EPS layup and they are also allowed to be used with Swissstop Black Prince pads. The scale of the failure is also catastrophic. Seeing the results here though have made me question the wisdom of their application in hillier terrain for larger riders.

- When rims get hot, they also wear faster. So a rim which is taken out of its comfort zone with heat will last less time than a rim which remains relaxed about its temperature. So Alto rims should last longer than other rims here on test. There are of course other factors at play and in our experience, we know of no-one who has managed to wear one of these rims out yet anyway.

- A major reason why at least some manufacturers would choose to avoid using the resins Alto use in their rims is the difficult of applying them (they require filament winding) and also their cost to procure. There may be other factors at play here but the cost of Alto rims to produce is extremely high, making their RRP extremely competitive.

- Impact resistance was questioned with these resins and manufacturers of carbon rims did experiment with phenolic resins to achieve maximum temperature resistance but the rims suffered with brittleness. This resin is not phenolic and Alto have done an impact test to demonstrate this here.

Thank you very much Spark Wheel Works for you assistance here in testing all these rims.

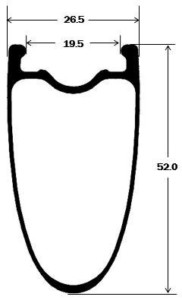

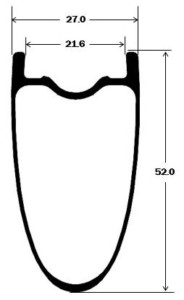

Alto CC52

The Alto CC52 is the most popular of the three rim brake depths. When buying a carbon aero wheelset, it is worth having a truly aero wheelset. Historically a rim this deep would be a handful and heavy; neither is the case on the CC52. It adds 50g/rim to the CC40. In the real world that means that the CC52’s depth will make it faster nearly all of the time. You would have to be climbing a steep hill at low speeds for the CC52 to be slower and even in hilly terrain, we come down as well as climb where the CC52 would be faster.

CC52 weights translate into approximately 1530g/pair with Tune Mig70/Mag170 hubs. By comparison – Chris King R45 hubs on the ENVE 4.5 rims would allow for a similar depth, and a weight saving of only 20g overall, making the Alto/Tune option exceptionally good value by comparison. That set isalso lighter and deeper than Zipp 303s. They are made with the same resin system that goes into the CC40 as well, so you can feel reassured even with the heaviest braking.

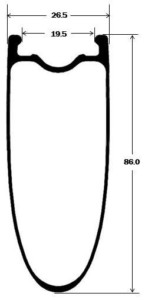

Alto CC86

86mm is deep. At this depth, you are less likely to be concerned about heat build up and braking and more about out and out speed. As with all of their rims, Alto do not release tunnel data on these rims – but feedback suggest they certainly are fast and stable. As with all Alto rims they are made to a superlative standard. At 672g the weight is good but less relevant given their area of application. Tubeless compatibility is a really nice feature to have on this. Joe Skipper on CC86 rims set the British Ironman record. Crucially too they are a comfortable setup, which makes them a sound choice for endurance events.

Alto CT40/CT52/CT86

Each of the key profiles has a tubular equivalent. The tubular rims provide a significant weight saving over their clincher counterparts but are far less popular owing to their comparative impracticality. The tubular rims nevertheless are nicely executed, still EPS moulded and possess similar profiles to their clincher counterparts. Weights for each are as follows:

CT40 – 365g

CT52 – 420g

CT86 – 550g

As with all Alto components. There is no rider weight limit on these rims.

Alto CC311/CT311 – prices subject to exchange rate.

- 1090/1260g

- 16 decal colour options

Alto say:

The world’s only tubeless compatible PMI core disc — the CC311 is the most advanced wheel on the market, with an aerodynamic profile and R-Symmetric shape designed to rip through the wind and give you that smooth-as-silk ride quality that Alto is all about. The CC311 hub is engineered for minimal wind resistance and manufactured in the USA with industry leading quality, using the same smooth internals as our standard hubs. The carbon shell and hub are bonded together using our proprietary epoxy resin and PMI Core, giving you a disc wheel with a stiffness-to-weight ratio that is second to none!

———

FEATURES:

- Weight: 1260g

- Clincher and Tubeless Compatible

- 25mm wide brake track for optimal stiffness and aerodynamics

- Shimano, SRAM, and Campagnolo Compatible

- Optimized for 11 speed and compatible with 10 speed

- Carbon Fiber with EPS Core Mfg Technology

- 25mm Clincher Tires Recommended

- Alto Skewers and SwissStop Black Prince Brake Pads Included

- Unlimited Rider Weight Limit

DCR says:

Atonishingly well made full carbon disc wheel. The CT311 will attract attention as the more traditional comparison but the CC311 should be the modern choice. Tubeless compatibility is rarely seen on these wheels and is a major bonus with Alto. Solid disc wheels often fall short on tolerances and adjustment/rebuilds are impossible on a wheel of that nature. So if you buy a disc wheel with naff hub internals, you are stuck with it. If it is out of true or dish, there is little you can do to change this.

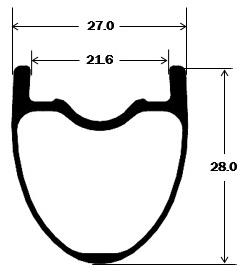

Alto rims – disc brake

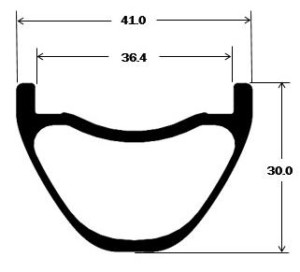

Alto CCX28/40/52

Unlike on their rim brake versions, Alto have provided a shallower, lighter carbon rim here. The CCX28 is the lightest clincher rim that Alto offer and is one of the lightest rims of its kind on the market. They have achieved this weight whilst maintaining no rider weight limit by making this a hookless design. The rim is very innovative in terms of its profile. It is well suited to road disc (25c and upwards), gravel and CX applications. Tubeless setup is easier without a hook and Alto internal testing actually indicated a rise in comfort on the rims as well (only by a small margin, but on some hookless designs the opposite is true).

There is a maximum pressure rating on these rims of 110psi which should be incrementally reduced as tyre size is increased. I would recommend for virtually all riders to run lower than this on 25c tyres anyway for greater grip and comfort. Being disc brake, heat will not be added to the rims raising pressures during use, so the hookless design is safe on this model where it would be ill advised on a carbon rim brake clincher rim.

Like in their rim brake lineup, there are three depths to choose, they have eliminated the very deep 86mm profile in favour of bringing in the much shallower 28mm profile. They did this in recognition of the different applications that the rims are likely to be used for. From my perspective, the 28mm and 52mm profiles are the most interesting in the range. The 28mm simply because it is the lightest. There are applications that these rims could be used for where aerodynamics would go out the window. In this case, why not simply have the lightest rim that you can find. Rims of this depth are often flexy, but Alto’s, like all of their rims, are very stiff laterally indeed. It is really quite remarkable how they have managed to use so little material to produce something of such strength and stiffness.

On the other end of the spectrum, the CCX52 profile provides the sort of aerodynamics that you would be looking for in a do everything road bike. The weight is still low enough that you could use the wheels for cyclocross if you wanted or take them on a hilly sportive. However if you wanted to munch up the miles on a flat course, this would provide significant drag reductions over the rest of the Alto carbon clincher disc range. Paired with a 25c tyre this is likely to be their fastest rim virtually all the time.

Weights for the range are:

CCX28 – 365g

CCX40 – 390g

CCX52 – 425g

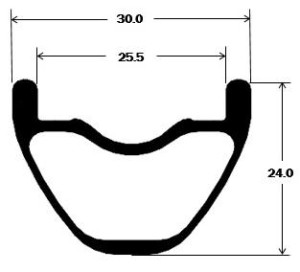

Alto MTB rims

Alto also offer a range of four MTB rims. Each of them hookless, all of them EPS moulded. There are two 27.5mm versions (650b/584mm) and two 29er (622) versions. Neither has a rider weight limit on them. The profiles are the same for each diameter, only the diameter varies. The wider versions are better suited to heavier duty applications and to wider tyres. The wider versions are also deeper. Profiles and weights are available below:

CMX275 – 650b – 375g

CMX275 Boost+ – 650b+ – 465g

CMX29 – 29er – 390g

CMX29 Boost+ – 29er+ – 490g

Each of these rims could be built up with a range of hubs of your choice, however Alto have designed them to be run with their hubs. The drillings for the narrower versions are 24h and 28h. The wider versions are available in 28h and 32h. So if you are pairing these carbon rims to the Alto disc hubs, you can pair both rims to the standard disc hubs along with their road disc/gravel rims. However it isn’t possible to pair their wider rims to their standard disc hubs.

We do of course carry a wide range of alternative hubs from Hope, DCR, Tune and DT Swiss which would allow alternative flavours should you wish.

Alto Wheelsets

There are lots of options to choose from here, please contact us for a price on a particular option, however here are a few examples to think about

Aforce Al33 rims, CX-Rays, Alto hubs – £975

Alto CC40 (40mm clincher), CX-Rays, DCR hubs – £1200

Alto CC40, CX-Rays, Tune hubs – £1540

Alto CC40, CX-Rays, Alto hubs – £1600

Alto CCX28, CX-Rays, DCR CL hubs – £1300

Alto CCX28, CX-Rays, Alto hubs – £1700

Alto wheels should be of particular interest but not limited to riders who:

- Have a high power output and can suffer with brake rub

- Ride at high speed and are looking for aerodynamic gains

- Whose weight falls out of the standard wheel profiling. I.e. heavier riders

- For those looking for absolute confidence when descending in the mountains

- Riders looking for increased comfort in their wheelsets

- For those looking for a very well produced range of wheel components for wheelsets in the £1000-2000 region.

Who are Alto Cycling?

College roommates and professional cyclists Bobby Sweeting and Shawn Gravois knew they could change the cycling industry after asking a simple question: where can the most performance benefit be gained? Their answer was immediate: the wheel. The two began to spitball the best ways to improve their own wheel sets, and a design idea was born.

Sweeting and Gravois spent a year perfecting the R-Symmetric hub geometry, designing their proprietary rim laminate design, and prototyping the entire system. The first test ride completely validated the entire concept, followed by quantitative testing that proved the ride was no fluke. In a standard rim deflection test, the Alto Velo CT56 wheel set tested 16.4% stiffer than the leading wheel brands in the industry.

Alto Velo officially launched in January of 2015, with three wheel options in their first product line—alloy clinchers, carbon clinchers, and carbon tubulars. In August of 2015, they announced a new line of disc brake wheels designed for road and cyclocross.

About the CEO:

Bobby Sweeting graduated Summa Cum Laude from the University of Florida with a BS in Mechanical Engineering. He is in his 10th season as a professional cyclist, currently racing for Smartstop Pro Cycling. Bobby began his career as a product design engineer in the rigid frames department of Cycling Sports Group where he worked with brands such as Cannondale, Schwinn, GT and Mongoose. After two years with the company, he served as a freelance product design consultant, where he provided design direction for multiple industry leaders. While designing, Sweeting founded Kinetic Potential Coaching, a coaching company that serves cyclists, runners and triathletes. In 2014, Bobby partnered with Shawn Gravois to found Alto Velo, where he oversees management of all design, production and sales teams.

About the CTO:

Shawn Gravois graduated Magna Cum Laude from the University of Florida with a BS in Mechanical Engineering. His work included designing and manufacturing pneumatic rocket launchers. Post-graduation, he returned to earn a MS in Solid Mechanical Design and Manufacturing. Shawn is in his ninth season as a cyclist, riding professionally for the Lupus Racing Team. Shawn began his career designing for various industry leaders before leaving the company to join forces with Bobby Sweeting in 2014 to design the R-Symmetric Flange, from which Alto Velo was born.

Below you can find some images of some of the Alto wheels we have built. More photos to come shortly. More available on DCR Wheels Instagram