Hubs

The hub is the central component of a bicycle wheel. A lot is demanded of it; it is a complicated component. Shell design and spoke bracing angle, bearing choice, axle diameter and material, as well as in rear hubs the drive mechanism and convertability, are all important factors. Hub design has a more profound impact on the characteristics of a wheelset than people may realise.

Good hubs are an investment. They are an investment in reliability and will in most cases outlast your rims. They can be serviced as time goes on and play a big role in the performance of your wheelset. Choosing one can be hard as manufacturers are not in a position to compare and contrast their product against others that are available.

There are 30 different hub models here organised by manufacturer in ascending price points, with the idea that DCR is able to offer a hub for any occasion. We start with our own range of hubs, which cover all disciplines from rim brake road through to gravel, cyclocross, MTB, touring and track. However there are also products from other premium brands for those looking for something slightly different. We laser etch or apply stickers to our own hubs and there are generally images of such hubs built up into wheels on our instagram feed.

Most items below are stock items; that means they should be held in stock at all times in quantity. Sometimes high demand means stocks run out but we strive to hold all that we can. That way you can expect more realistic lead times with these components. If an item below is out of stock, we will let you know a realistic lead time based on the manufacturer or distributor’s quoted date. If you want to buy the components on their own, please get in touch.

We have listed below, product information on:

- Rim Brake

- Disc Brake (Centrelock and 6-Bolt)

- Dynamo

- Track (coming soon)

- Internal Gear

Rim Brake Hubs

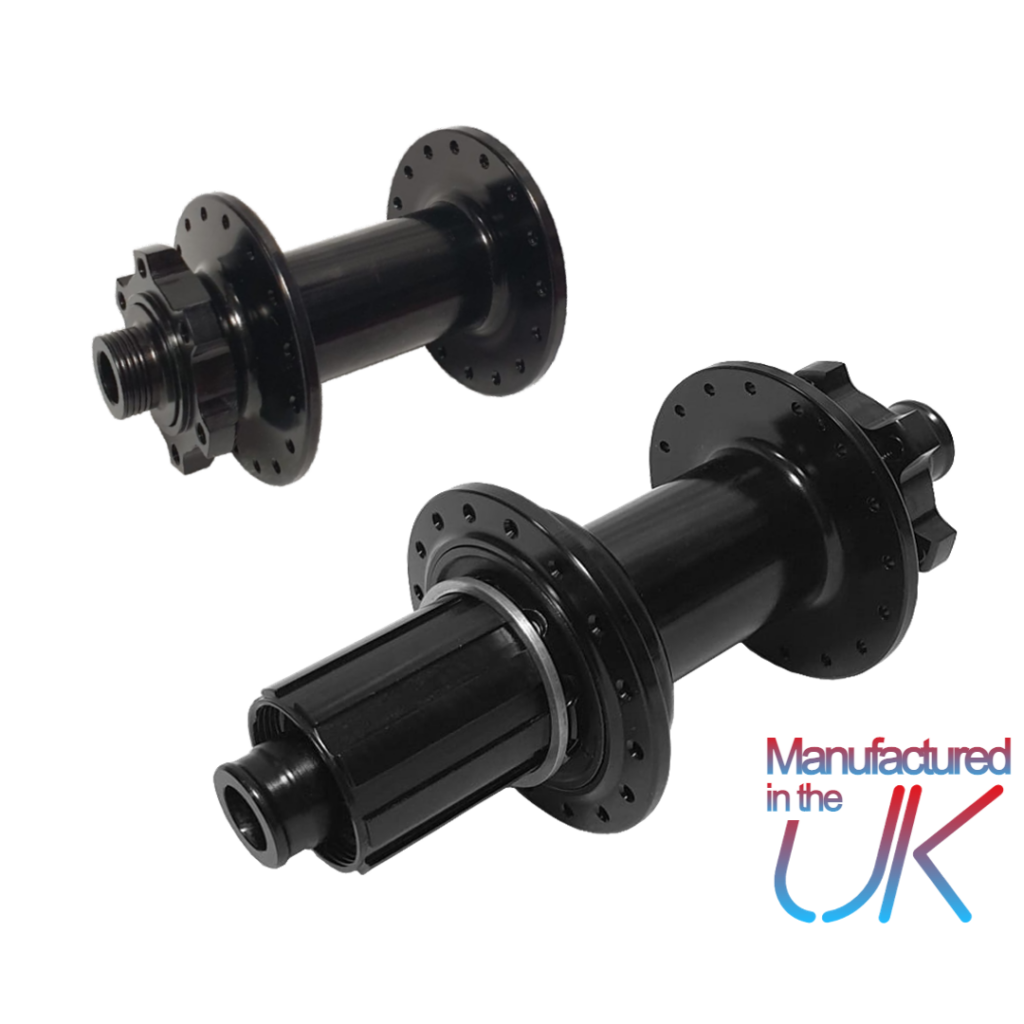

DCR Rim Brake Hubs

DCR hubs set a new benchmark in wheel performance. They have been developed to meet the demands of serious riders in the UK whilst offering exceptional value for money. The components themselves come directly from factories/workshops from a range of manufacturers. I have not given the full details of all the modifications here. All DCR components have a 2 year manufacturer’s warranty.

All DCR hubs are made abroad – I do not want to give the impression they are made in house. However they also all have additional work done to them here – they have a dedicated UK weather treatment applied to them and they are treated to make their ratchets quieter and more durable. Here are some particularly important features about the DCR road hubs:

DCR Rim Brake Front – 85g

Weight is a highly subjective thing. I sell front hubs that still take J bend spokes that can be as light as 33g. So you may say that this hub is heavy. However it is still more than 15% lighter than a Chris King R45, DT Swiss 240, Shimano Dura Ace or a Royce Ultra Light. It is also lighter than a White Industries T11 and only a little heavier than a Tune Mig70.

For me the most important element as to why it makes such sense is because it has a wider bracing angle, a robust axle interface and heavier, high quality bearings. The reasons for all of these are in pursuit of strength, stiffness, riding comfort and durability. The carrying capacity of the bearings in the DCR hub is more than double that of a NovaTec A291-SL. The bracing angle is over 25% bigger which means that the wheels it builds into are both stiffer and more comfortable. The axle interface is a screw fit, rather than a push fit which, while being heavier is stiffer, particularly as the bearing loading is closer to the dropout which also places less strain on the axle. You do have to be careful when lacing with this hub because sometimes if laced tangentially the spokes can foul your fork – it depends on the fork design. Radial lacing is allowed on these hubs and should be used to allow a fit on certain forks. For radial or tangential lacing 100kgf will be applied to the spokes. Two 6900 bearings are used here, made by TPI and are ABEC 5.

DCR Rim Brake Rear – 210g

While I would love to report a massive bracing angle on the drive side, it simply is not possible on any 130mm spaced 11s compatible road hub. Cassettes are just too big. The bracing angle on this determined by flange spacing is similar to what you will find in a White Industries, Tune, Chris King, Royce and NovaTec hub. Due to the problems you get with this bracing, it is important that rims which can tolerate at least 120kgf are used.

The weight is very competitive on these rears – lighter than White Industries, Chris King, Royce, DT Swiss 240 and NovaTec. My key emphasis with these hubs has been durability and sealing against the elements. The quality of the seals is very good on them and they have ABEC 5 TPI bearings again 2×6902 and 2x 6802. As with the front, they have been weather treated, the ratchets also have a special treatment applied to keep the mechanism quiet and durable. There are 6 pawls inside the hub which engage in two groups for 48 points of engagement. The pawls and ratchet are steel. The external sealing on the hubs is soft to help guard against water intrusion but this does add a small amount of drag (comparable to a lot of hubs and less than Royce for example but more than some low friction hubs like White Industries). The axles are 15mm which helps to keep builds stiff, so do the textured end caps. All hubs come with a spacer for running 8/9/10 speed cassettes. The axles and freehub body are made from 7075 aluminium. A cassette with an alloy carrier is strongly recommended. The shells are 6061 aluminium. For a £120 upgrade, you can buy a heavily machined titanium freehub body, however I recommend starting with the alloy. If you torque your lockring to 40nm, I would be surprised if you suffer with ‘bite’.

DCR Touring Rim Brake

The DCR Heavy Duty/Touring hubs have extra bearings for increased carrying capacity. The front hubs have four instead of two cartridge bearings and the rear hub shell and freehub have an extra bearing each, making a total of ten bearings overall. They also have steel axles and a steel freehub instead of aluminium. The spoke holes are drilled for Sapim ‘Strong’ spokes. All of this makes them suitable for carrying impressive weights – I’ve sold these to riders whose total system weight is over 150kg. I would suggest these to anybody who expects to ride with a system weight of over 130kg, including heavily laden touring riders. Disc brake (including boost spacing) versions are also available.

Hope RS4 Rim Brake

Hope Hubs are made in the UK and offer a good level of reliability and strength, some say at the expense of weight savings. They have good sized, high quality bearings which are very well sealed and protected, as well as 15mm axles which is the minimum I like to see on any aluminium axle. They’re easily convertible and Hope carry all spares, which are readily available. While they’re not the heaviest hubs we sell, they’re not as light as most other brands here including DCR. Their large flanges are very strong however, and offer a good option for road and touring riders who run a system weight above the 85kg weight limit on the lighter DCR hubs. They are available in a wide range of colours including black, silver, blue, orange, purple and red.

DT Swiss 350 Rim Brake

DT Swiss hubs are made to a very high standard, again with 15mm axles and high quality Japanese, corrosion resistant stainless steel bearings which are well protected from the elements. Their shells are forged aluminium. Their use of their own revolutionary star ratchet design instead of traditional pawls and springs means fewer small moving parts – they are considered by many riders and wheelbuilders to be ahead of the rest in terms of reliability, without the weight penalty usually associated with such a label. DT Swiss say of the 350; ‘while the lighter 240 EXP hubs get all the glory, the 350 does all the work’. The 350 still uses the original star-ratchet design previously used in the legendary 240s hubs until their relaunch as the 240 EXP in 2021. Spares are available and the axles and freehubs are easily convertible.

DT Swiss 240 EXP Rim Brake

Their previous incarnation, the 240s, set the benchmark for ultra-reliable performance hubs and developed an outstanding reputation over twenty or so years. Their replacement, the 240 EXP (launched in 2021) have improved over their predecessors by being lighter and containing even fewer moving parts. This has been achieved through a redesign of their ratchet and the use of different bearings. Instead of two individually sprung ratchet rings, now there is one stationary ring and one which is sprung. The size choice of 15x26x7 bearings over the original 6902 bearings hasn’t proved to be detrimental to their carrying capacity or reliability and all six cartridge bearings throughout the hubs are the same size.

DT Swiss 180 EXP Rim Brake

The 180 hubs are among the most expensive we sell and it is fairly difficult to see how they justify such a steep price increase over the 240. They do come with ceramic bearings, which account for most of the weight saving. Straight pull models available only.

Nevertheless they are strong, durable, light, high performance hubs. If you wanted a no-compromise pair of hubs that weigh in towards the lighter end of the spectrum but still need them more rugged, and don’t mind the price tag, these would be a good choice.

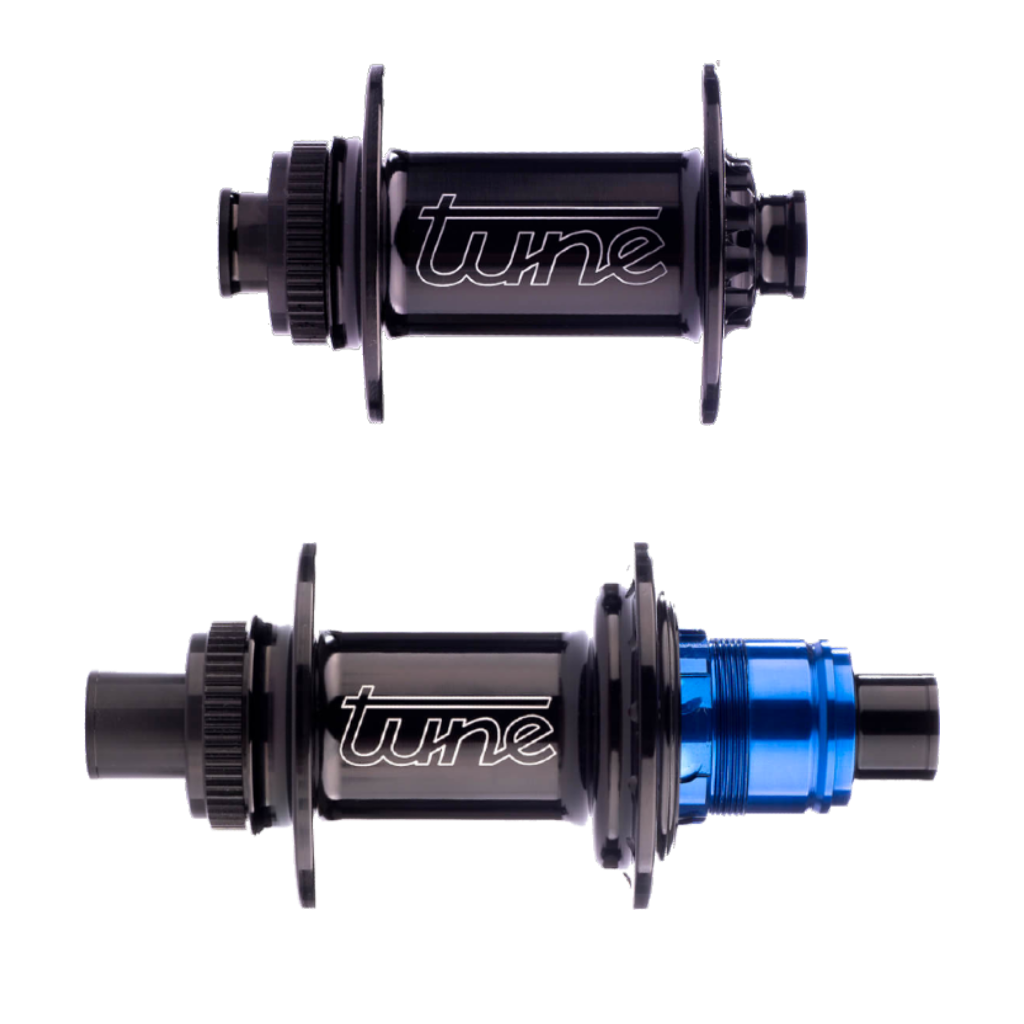

Tune Mig and Mag

Now we’re getting into really lightweight territory. Tune hubs have performance and weight saving as their key focus, but with Tune this doesn’t mean you’re sacrificing reliability. They have gone for large, 17mm axles to help with both stiffness and durability. While they have gone with fairly small bearings, they have very high quality sealing on them and they have gone with a 6903 on the drive side rear where it really matters. You can tell from the design that longevity has not been overlooked.

The nature of the forging, tempering and machining of the shells makes them exceptionally strong. 7075 is already a strong alloy but the forging keeps the molecules all pointing up the flanges to keep their tensile strength to a maximum.

On the front hub, (28h drilling and below) radial lacing is not only tolerated but recommended. The hub has a different drilling in order to cope with this. The axle loading system means that even with high clamping force there is no bearing misalignment. The front flanges rotate slightly to align themselves with the rims to ensure that the perfect spoke angle is achieved. The MIG/MAG pair is one of the highest performing hubsets going – great for stiff, light wheels.

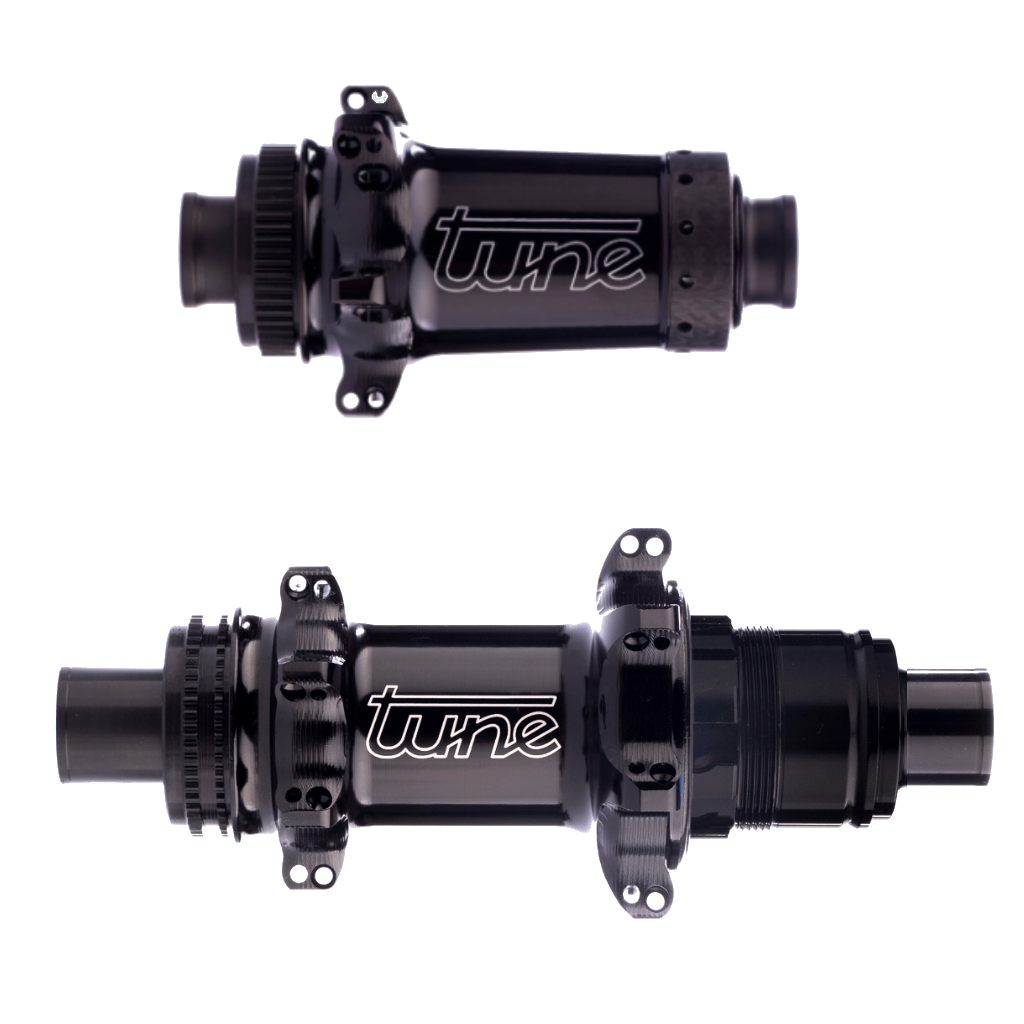

Tune Mig Skyline and Mag Skyline

These are among the lightest hubs available anywhere. All the features of the standard Mig and Mag design but with extensive machining on the shells with some carbon fibre replacing aluminium to save weight but maintain strength and stiffness. To top this, the bearings have been replaced with ceramic bearings, which adds up to makes them a sound choice for for riders looking for zero compromise when it comes to rolling resistance and weight saving.

Carbon-Ti X-Hub Road SP

Again, these are among the lightest high performance hubs you can buy. They are made in Italy. They use a preload system to save weight as this negates the need for material over the axle between the bearings. They also have very fast freehub engagement, high quality SKF bearings and like the Tune hubs they have a very stiff, strong 17mm axle. Most of all, they build into very light, strong wheels, offering good spoke bracing angles.

Along with the Tune Skyline hubs, they require straight pull spokes so we only build these with CX-Rays. This is to be expected however, as the owner of such a prestige set of hubs shouldn’t settle for anything less.

Disc Brake Hubs

DCR Centrelock Hubs

The DCR centre lock is one of our most popular hubs owing to its huge versatility. The front can easily be converted between quick release, 12mm and 15mm through axles. The rear can be 135mm qr or 135 x 10, 135 x 12 or 142 x 12mm through axles. Like all DCR rear hubs, the freehub can be Shimano HG, Campagnolo (including N3W), XD, XDR or Microspline compatible. The Shimano HG freehub bodies come fitted with steel anti-bite splines as standard.

The hubs come in a broad variety of colours, which we keep in stock in most drillings – please enquire for availability. If you run a centrelock to 6-bolt converter, you can also fit any 6 bolt rotor on these hubs. However, people often prefer to install 6 bolt rotors on 6 bolt hubs – for that you are better off using our standard disc.

The weights of the hubs vary a bit depending on the combination. For example, the 15mm end cap weighs less than the QR cap. The 135mm x 12mm through axle is also the lightest for the rear. Weights for the hubset start at 370g. Boost-spaced hubs are also available.

DCR Standard Disc/6-Bolt Hubs

These are tougher and slightly heavier than our centrelock hubs. They can be used for a broad range of applications and have larger flanges allowing for different drillings. They weigh 170g front, 290g rear. Certainly these are no heavyweights but they are designed to be bigger, tougher hubs than the dedicated road disc versions. They have the same 6 pawl engagement system as the other hubs only these are on a 54pt engagement rather than 48pt. The front hub is convertible between quick release, 12mm, 15mm and 20mm through axles interfaces. For the front end, there is also a lighter (in duty and weight), convertible front hub which really comes in significantly lighter at 120g. Boost-spaced hubs are also available.

Many people consider the Hope Pro 4 a benchmark when it comes to a disc hub. Personally I would say that our own disc hubset sets the benchmark for me, being both lighter and cheaper than the Pro 4. Our hubs also despite rigorous testing have provided no issues when it comes to toughness or durability and are easily serviced.

DCR Professional Disc Hubset

This is something we have been working on for years. It’s a product range we are also looking to expand in time and something that was far harder to get off of the ground than we ever imagined! We wanted a pair of hubs here that you could absolutely thrash but didn’t cost or weigh much either. The design has been comprehensively tested and comes with a two year warranty (not including bearings).

2.4mm thick axle (for those not familiar with axle thickness, this is approximately very thick)

6 pawls offset into two groups of 3

27t ratchet ring

54 points of engagement

Labyrinth seals on the external caps and for the freehub. The freehub seal is an interference fit on the hub shell with the labyrinth running freely in a groove in the freehub itself. The seal is very easy to install however as we know it can be very fiddly on some other British made hubs…..

The hub is a stacked system end to end. The end caps are an interference fit, no threading and no loosening. It’s a snug fit with a rubber o-ring providing the interference. The stacking is spaced between the freehub and hub shell bearing with a thick alloy washer/spacer to prevent damage to the axle at this point.

17287 and 6903 bearings are used in the hubs depending on the model/location. We carry spares for their replacement.

The end caps and freehubs are interchangeable to allow easy subsequent conversion. The front hubs can easily be changed between boost and non-boost. The rear hubs are boost/non-boost specific.

These hubs are ideally suited to all types of rider and riding. They are a fit and forget workhorse at an entirely reasonable price. We very much look forward to expanding the range in the future to include centrelock hubs, colours and other drillings so watch this space.

We offer a free laser etching service on these hubs. Have your logo or name etched onto the hubs in a high quality, permanent finish. Contact us for details.

DCR Heavy Duty / Touring Disc

DCR hubs have been developed to meet the demands of serious riders in the UK whilst offering exceptional value for money. This includes riders who carry lots of weight. All DCR components have a 2 year manufacturer’s warranty and have a dedicated UK weather treatment applied to them here in the DCR workshop.

The DCR Heavy Duty Disc/Touring Disc hubs have extra bearings for increased carrying capacity. The front hubs have four instead of two cartridge bearings and the rear hub shell and freehub have an extra bearing each, making a total of ten bearings overall. They also have steel axles and a steel freehub instead of aluminium. The spoke holes are drilled for Sapim ‘Strong’ spokes. All of this makes them suitable for carrying impressive weights – I’ve sold these to riders whose total system weight is 180kg. I would suggest these to anybody who expects to ride with a system weight of over 130kg, including heavily laden touring riders and E-Bikes. Boost-spaced hubs are also available.

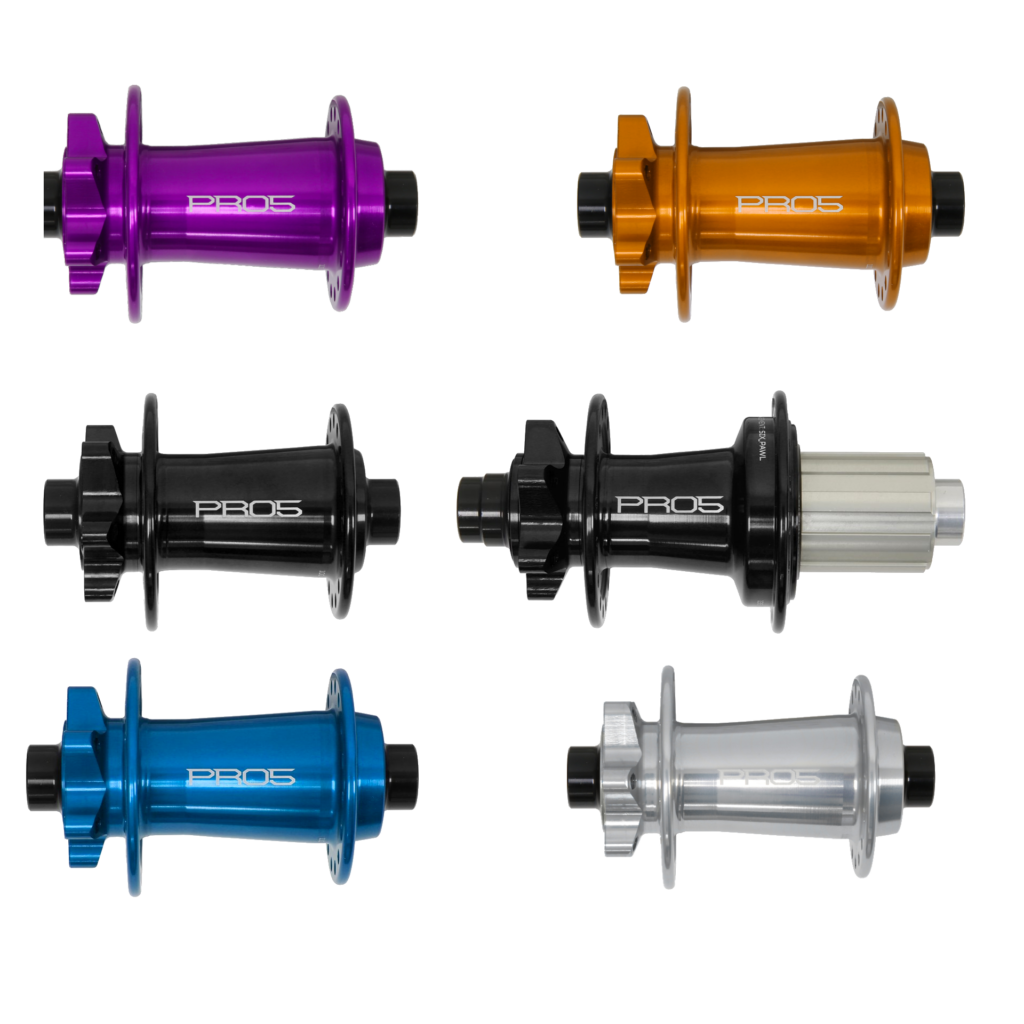

Hope Pro 5 Centerlock or 6-bolt Hubs

Hope Hubs are made in the UK and offer a good level of reliability and strength, some say at the expense of weight savings. The Pro 5’s are the replacement for the Pro 4 and the RS4. They’re tough, come with good sized, high quality bearings which are very well sealed and protected, as well as large axles which I like a lot. They have a new freehub seal. They also have an increased loading capacity while offering reduced drag from a new, wider freehub spring design. The engagement speed for the aluminium freehubs has been increased to 108 points, which is one of the fastest available here. The steel freehubs have 54pts of engagement. They’re easily convertible and Hope carry all spares, which are readily available. While they’re not the heaviest hubs we sell, they’re not as light or affordable as some brands here including DCR. They have a well-earned reputation for being strong and reliable. They’re available in a wide range of colours including black, silver, blue, orange, purple and red.

The Pro 5 CL hubs are the replacement for the old RS4 CL hubs. The freehubs are sold with 6 pawls, which is an improvement over the old hubs which were sold with 2 or 4. They even give you a choice of aluminium or steel. They were famous for their noisy freehubs although the volume has been dialled down compared to how they used to be. Some riders may be disappointed to hear this, however. The volume is ultimately down to how much grease you run in the ratchet. Hope hubs use leaf springs instead of small coil springs – some of you who service you own hubs may prefer this.

DT Swiss 350 Disc Hubs

DT Swiss hubs are made to a very high standard, again with 15mm axles and high quality Japanese, corrosion resistant stainless steel bearings which are well protected from the elements. Their shells are forged aluminium. Their use of their own revolutionary star ratchet design instead of traditional pawls and springs means fewer small moving parts – they are considered by many riders and wheelbuilders to be ahead of the rest in terms of reliability, without the weight penalty usually associated with such a characteristic. As is often the case, the 6-bolt version has larger hub flanges and is slightly heavier duty.

DT Swiss say of the 350; ‘while the lighter 240 EXP hubs get all the glory, the 350 does all the work’. The 350 still uses the original star-ratchet design previously used in the legendary 240s hubs until their relaunch as the 240 EXP in 2021. Spares are available and the axles and freehubs are easily convertible.

DT Swiss 240 EXP Disc Hubs

Their previous incarnation, the 240s, set the benchmark for ultra-reliable performance hubs and developed an outstanding reputation over twenty or so years. Their replacement, the 240 EXP (launched in 2021) have improved over their predecessors by being lighter and containing even fewer moving parts. This has been achieved through a redesign of their ratchet and the use of different bearings. Instead of two individually sprung ratchet rings, now there is one stationary ring and one which is sprung. The size choice of 15x26x7 bearings over the original 6902 bearings hasn’t proved to be detrimental to their carrying capacity or reliability and all six cartridge bearings throughout the hubs are the same size.

The 240 EXP hubs have been used by racing cyclists on anything from local crits to the grand tours, on long distance events such as the Transcontinental Road Race and in the extremely tough worlds of MTB downhill and cross country racing. They have earned their reputation and are popular with wheel builders.

DT Swiss 180 EXP Disc Hubs

The DT Swiss 180 EXP disc hubs are available in centrelock only. They are among the most expensive we sell and it is fairly difficult to see how they justify such a steep price increase over the 240. They do come with ceramic bearings, which account for most of the weight saving. Straight pull models available only.

Nevertheless they are strong, durable, light, high performance hubs. If you wanted a no-compromise pair of hubs that weigh in towards the lighter end of the spectrum but still need them more rugged, and don’t mind the price tag, these would be a good choice.

Tune Kill Hill/Climb Hill Disc Hubs

Formerly known as the King and Kong, the KillHill (front) and ClimbHill (rear) hubs are the standard ones, with regular aluminium flanges. However, to say standard sells them short really, they are forged and then machined to ensure perfect alignment of the molecules in the 7075 alloy. This makes the shells incredibly strong. The bodies are made from a material unique to Tune, the full details of which I am not allowed to release. However it is tougher than 7075 making it better at resisting cassette bite and the whole setup is more durable. They also have a titanium drive system which uses two different types of titanium alloy to ensure longevity.

Now we’re getting into really lightweight territory. Tune hubs are up there with the lightest you can buy. However, although the company may have performance and weight saving as their key focus, with Tune this doesn’t mean you’re sacrificing reliability. They have gone for large, 17mm axles to help with both stiffness and durability. While they have gone with fairly small bearings, they have very high quality sealing on them and they have gone with a 6903 on the drive side rear where it really matters. You can tell from the design that longevity has not been overlooked.

The KillHill/ClimbHill hubs are available in centrelock, although the boost hubs are available in 6-bolt.

Tune Prince and Princess Disc Hubs

Tune Prince and Princess disc hubs are among the lightest hubs available anywhere. All the features of the standard design but with extensive machining on the shells, with some carbon fibre replacing aluminium to save weight but maintain strength and stiffness. To top this, the bearings have been replaced with ceramic bearings, which adds up to makes them a sound choice for for riders looking for zero compromise when it comes to rolling resistance and weight saving.

The Prince and Princess hubs are available in centrelock, with the boost-spacing hubs available in 6-bolt.

Carbon-Ti SP Centrelock X-12 Disc Hubs

Again, these are among the lightest high performance hubs you can buy. They really are very impressive. They are made in Italy. They use a preload system to save weight as this negates the need for material over the axle between the bearings. They also have very fast freehub engagement, high quality SKF bearings and like the Tune hubs they have a very stiff, strong 17mm axle. Most of all, they build into very light, strong wheels, offering good spoke bracing angles.

I only keep stock of the black hubs, although other colours are available from Italy with longer lead times. The following colours are available to order: green, acid green, silver, gold, red and blue. These colours are special order only.

These can be built into wheelsets weighing under 1180g. This doesn’t mean you have to sacrifice stiffness either – the large, 17mm axles see to that. They are an attractive option for any gravel or road cyclist with disc brakes looking for premium hubs, and we have boost options for MTB riders.

Along with the Tune Skyline hubs, they require straight pull spokes so we only build these with CX-Rays. This is to be expected however, as the owner of such a prestige set of hubs shouldn’t settle for anything less.

Chris King R45 Disc Hubs

Chris King R45 hubs are available through DCR Wheels. The R45 is a real classic for those looking for a performance road hub. It suits those looking for longevity; Chris King believe in hubs you can service yourself that will last for many years, potentially never wearing out if you service them regularly. This servicing is crucial to their longevity and is ideally carried out at least once a year, although Chris King recommend even more often than this. DCR Wheels is proud to offer this service.

Chris King make their own bearings, and are not made to standard sizes. You can spec your hubs to have steel or ceramic bearings. The angular contact bearing system does need checking regularly and adjusting periodically. This is best done by using two 5mm allen keys and their own cone asjusting tool, also available through DCR Wheels. The complete service tool kit is available to buy which will allow you to service the hubs themselves, please enquire for details.

Chris King rear hubs use their unique patented ring drive system. Chris King say: This unique design offers instant, positive engagement that is over 3 times quicker than a standard 24-tooth pawl-type freehub. RingDrive™ uses 72 engagement teeth on stainless steel drive and driven rings for a system that is capable of handling torque load of over 800 ft/lbs.

It is important to understand a Chris King Engagement as being more than simply 72 points of engagement. The actual lag between pedalling and engaging is faster than that suggests because of the nature of the ring drive whereas a pawl will have to run down into a groove. The engagement does feel very fast indeed. The hubs also have oversized shells and axles and bearings which all improve strenght, longevity and stiffness.

These are among the most expensive hubs available through DCR Wheels. Chris King customers tend to really love their hubs and they attract a certain loyalty – look after your hubs and they will look after you for many, many years.

Dynamo Hubs

Schmidt and SON Dynamo Hubs

DCR Wheels proudly offers the full Schmidt range. It is important to understand this range correctly. The Klassik is an old design, not used much any more. The ’28’ is the replacement for the Klassik. The ‘Delux’ was originally designed for smaller wheels – it produces a lower output at lower speeds but it actually produces a higher output at high speeds. The 28 has a wider bracing angle than the Delux. The Delux is lighter. Both are as strong as each other. I have a ’28’ on my touring bike and I absolutely love it; and have only experienced happy owners of either model of hub.

The Delux offers lower drag at lower speeds than the 28, making it a good choice for faster riders, whereas the constant output (no matter the speed) of the 28 makes it a better choice for slower or heavy laden touring riders.

Both models are available in quick release or thru-axle models. The quick release models are cheaper and may suit you now, however I recommend buying the thru-axle model if your budget can accomodate it. Even if you currently run quick release (an adapter is available), a new bike a few years down the line might only come with a thru-axle fork which the quick release hub cannot be adapted to work with.

Schmidt dynamo hubs are arguably the best hubs available to purchase today. Certainly if what you are looking for is longevity, they are tough to beat. They are generally rated at 40,000km between service intervals. The sealing on them is superb and the modern versions are competitive when it comes to weight and drag.

Lighting and other accessories

The full range of B&M lighting and charging products are available to go with your dynamo wheelsets. The CYO IQ, IQX, Luxos U and USB-Werk are among the most interesting products in their range. Those of us who run dynamo lighting systems here at DCR all use Schmidt hubs and B&M lights. They are designed to have intelligent beam patterns, to strict German laws about not dazzling oncoming road users. Please enquire for more details on what we recommend and what’s available.

Internal Gear Hubs

Rohloff

The full range of Rohloff hubs is avaiable to order through DCR Wheels at competitive prices. There are a lot of options to choose from, so make sure you get the right hub. Generally I recommend disc brake compatible versions as it helps to future proof the hub, going for a solid spindle version will also increase compatibility in the future. Rohloff have a speedhub finder on their website which is very helpful, but if you want any advice about ordering a hub, please get in touch.

The Rohloff hub is one of the most expensive in the world. Partly because it is manufactured to a high standard but mainly because of what it is expected to do. The Rohloff has 14 internal hub gears. This means you have no need for: external cassette, front mechanism, rear mechanism, front shifter or more than one front chainring. Just one simple shifter that can be used stationary or during pedalling. No-one manufactures a hub that has 14 internal gears apart from Rohloff.

For more information, please read David’s article: Building With A Rohloff Hub.

Shimano Alfine 11

If anyone is going to make a hub that comes close to a Rohloff, it’s going to be Shimano, isn’t it? They have moved away from the technology that they used in the Alfine 8 in favour of Rohloff’s oil bath system. They have also made a hub that is roughly than half the price of the Rohloff (in some interations). It is also a little bit lighter than the Rohloff and smaller. It can come with with a fairly standard rapid fire shifter or with Di2. This uses a normal cable and shifts in the same way that modern Shimano MTB shifters do.

By contrast, it has 11 rather than 14 gears. With a range of 408.5% – less than the Rohloff. The Rohloff also shifts in even 13.6% increments, whereas the Alfine has a particularly easy first gear followed by a jump to second where it proceeds in fairly even increments of a similar percentage to the Rohloff hub.