What MTB rim should I choose?  What a question….well, it enormously depends on the type of riding you are doing. However, there are different diameters, different profiles, different materials, different tubeless interfaces, different brake types and essentially different grades of toughness. For the purposes of this we are ruling out Fatbike, some plus rims and rim brake rims as well as 26” rims. Some of these profiles are available in 26″, if you want a good disc brake 26” rim then the most popular option is the Ryde Trace Trail 25 as a good all round option. Some rims are asymmetric, some are asymmetric optional. Asymmetric function depends on the hub choice as well as general design, if done well it is a great feature but not always necessary. We have ignored asymmetric designs here but it could be a good bonus feature, especially on lighter XC rims on non-boost hubs. What most riders want is the lightest rim that is tough enough for their needs.

What a question….well, it enormously depends on the type of riding you are doing. However, there are different diameters, different profiles, different materials, different tubeless interfaces, different brake types and essentially different grades of toughness. For the purposes of this we are ruling out Fatbike, some plus rims and rim brake rims as well as 26” rims. Some of these profiles are available in 26″, if you want a good disc brake 26” rim then the most popular option is the Ryde Trace Trail 25 as a good all round option. Some rims are asymmetric, some are asymmetric optional. Asymmetric function depends on the hub choice as well as general design, if done well it is a great feature but not always necessary. We have ignored asymmetric designs here but it could be a good bonus feature, especially on lighter XC rims on non-boost hubs. What most riders want is the lightest rim that is tough enough for their needs.

What width do I need?

Wider rims hold wider tyres better. We have not listed any ‘narrow’ rims here, with the narrowest being 22mm internal. Until quite recently 21mm interal was actually considered wide, but rims have got wider and wider allowing for a nicer tyre profile and better grip. For further reading, you may find ENVE’s article on wider not always meaning better of interest. If you do not want to read that, basically, you do not need a particularly wide rim if you are not running a wide tyre.

What diameter do I want?

Well, 26″ was the standard for many years. However, that has been almost completely abandoned by bike and frame manufacturers. It is still widespread as it was the standard for many years. 650b is a less common standard now than 29er, however, there are quite a lot of 650b+ compatible frames coming out, many of which also work with ordinary 29er wheels as they are essentially the same size, which could offer some rare versatility for riders looking to try both ‘sizes’. In reality you are not really varying your size, just the amount of your overall diameter that is wheel and the amount that is tyre. For this you will need clearance for a bigger tyres.

It is beyond the scope of this discussion to wade into which diameter is better. Nearly all of the rims below are available in  650b, some only in 650b which have been annotated “584”. For comparison, we have stuck with the 29er weights for all rims where possible, if there is no 29er rim, we have declared 650b weight. What is relevant here is, bigger wheels if all else is equal will always be weaker, flexier and heavier. So a larger wheel needs to make up for those compromises in other ways such as a better ability to roll over obstacles, you may also need a slightly tougher/stiffer rim if you are running 29er wheels than 650b.

650b, some only in 650b which have been annotated “584”. For comparison, we have stuck with the 29er weights for all rims where possible, if there is no 29er rim, we have declared 650b weight. What is relevant here is, bigger wheels if all else is equal will always be weaker, flexier and heavier. So a larger wheel needs to make up for those compromises in other ways such as a better ability to roll over obstacles, you may also need a slightly tougher/stiffer rim if you are running 29er wheels than 650b.

Something that I very much dislike about the whole discussion and I want to set straight right now is the names! 26″, 650b (27.5) and 29er are all different sorts of names and can be very misleading. It has been made worse now as 26″ being more of a historical standard goes into a big list of historical standards, many of which start “26 x”. So let’s clear this up. 26″ is 559. That is the actual bead diameter in mm. ‘650b’ is 584. 29er is 622. Yes, 622 is the same as the much more stable road standard often, unhelpfully called 700c. So 584 is 25mm bigger than 559. 622 is 63mm bigger than 559 and 38mm bigger than 584. Narrower 29er rims being the same diameter as road rims can then also be used for cyclocross or gravel or potentially even some road disc applications. Equally some road disc bikes designed around narrower road tyres can also use 650b rims with 650b MTB tyres on, allowing for a very versatile gravel bike.

There are too many options!

Items which we are particular fond of are the DCR XC/AM for being excellent value and all the rim that most riders could ever need. DT EX471 for being tough enough for downhill use despite being an Enduro rim and not out of place as an all mountain rim – see Aaron Gwin’s amazing downhill run with no tyre if you are not convinced. The alloy and extrusion techniques used in that rim are the same as those in the rest of the DT series listed here. There is also the Ryde Trace 25 for being pretty much the perfect rim profile for delivering excellent weight saving and maximum stiffness especially due to its internal bracing as well as great resilience against impact. If you just want comparatively cheap and light, the Ryde Edge 22 is a good option. To give you an idea on cost, if you double the rim cost and add £220, that is the cost for that rim built up with DCR disc hubs in any interface with Sapim D-light spokes. Or you could have any of these built with your hub of choice, be that DT Swiss, Tune, Chris King, Onyx, Phil Wood, Alto or a host of other alternatives, just let us know.

How do I compare them?

Below is a basic chart to outline some key differences between the rims – if you like a ‘short’ list of vital statistics. However, there are a lot more details that could be elaborated upon. All of the rims are tubeless compatible. When it comes to application, we have indicated either Cross Country (XC), All Mountain (AM), Enduro (EN) or Downhill (DH) and (+) for Plus sized rims. That is a spectrum for the rims intended function. The idea of the list is to allow you to easily cross reference width, weight, cost and intended function. The functions are determined by the manufacturer and not by us, so they could be being cautious or optimistic in what they feel their rim can stand up to. Some rims have been omitted if we do not like them for some reason. A common reason is tension tolerance, we like all rims to be able to handle a minimum of 110kgf which

DCR XC AM

rules out all Mavic and some NoTubes rims. We may also have omitted rims because we do not know about them, have no experience with them or that they are not readily available. Welding is a nice feature and normally a mark of a higher end rim in that all cheap rims are not welded. However, cheap rims are generally pinned and none of those are featured here. Sleeve rims can still be strong and compete well on strength:weight. Some extrusions can make welding very difficult. A welded joint makes the alloy continuous and tubeless setup easier. Often a lack of weld simply indicates that the manufacture or brand’s chosen factory is not tooled for welding.

A shallow bead hook as developed originally by NoTubes makes rims better at resisting impact at the bead. That is not to say that the rim itself is better at resisting impact.

| Model | Width (internal) | Alloy | Joint | Weight (29er) | Application | Cost |

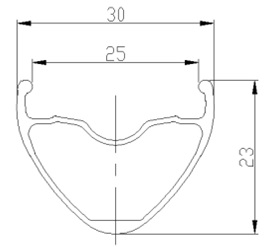

| DCR AM/EN | 25mm | 6066-T6 | Welded | 480g | AM/EN | £50 |

| DCR Big Boy | 30mm | 6066-T6 | Welded | 490g | AM/EN | £65 |

| DCR XC/AM | 25mm | 6066-T6 | Welded | 435g | XC/AM | £50 |

| DT EX471 | 25mm | Secret!! | Welded | 530g | AM/EN | £70 |

| DT EX511 | 30mm | Secret | Welded | 535g (584mm) | AM/EN/DH | £90 |

| DT XR361 | 22.5mm | Secret | Welded | 410g | XC/AM | £75 |

| DT XM421 | 25mm | Secret | Welded | 465g | XC/AM/EN | £80 |

| DT XM521 | 35mm | Secret | Welded | 545g (584mm) | XM/AM/EN | £80 |

| Easton Arc 24mm | 24mm | 6061? | Welded | 455g | XC/AM | £85 |

| Easton Arc 27mm | 27mm | 6061? | Welded | 515g | XC/AM | £85 |

| Easton Arc 30mm | 30mm | 6061? | Welded | 535g | XC/AM | £85 |

| Easton Arc + 35mm | 35mm | 6061? | Welded | 578g | AM/EN/+ | £100 |

| Easton Arc + 40mm | 40mm | 6061? | Welded | 633g | AM/EN/+ | £100 |

| Easton Arc 45mm | 45mm | 6061? | Welded | 690g | AM/EN/+ | £100 |

| E*thirteen TRS+ | 23.4mm | EXAlite | Welded | 470g | XC/AM/EN | £90 |

| E*thirteen LG1+ | 28mm | 6061? | Welded | 518g (584mm) | DH | £90 |

| NoTubes Arch MK3 | 23mm | 6069 | Welded | 453g | XC/AM/EN | £68 |

| NoTubes Flow MK3 | 29mm | 6069 | Welded | 527g | AM/EN/DH | £68 |

| Ryde Edge 22 | 22mm | 6061 | Sleeve | 410g | XC | £47 |

| Ryde Edge 26 | 26mm | 6061 | Sleeve | 525g | XC/AM | £47 |

| Ryde Edge 30 | 30mm | 6061 | Sleeve | 560g | XC/AM/EN | £47 |

| Ryde Trace 22 | 22mm | 6061 | Sleeve | 355g | XC | £70 |

| Ryde Trace 25 | 25mm | 6061 | Sleeve | 465g | XC/AM/EN | £70 |

| Ryde Trace 29 | 29mm | 6061 | Sleeve | 515g | XC/AM/EN | £70 |

| Velocity Blunt SS | 26.6mm | 6061 | Sleeve | 425g | XC | £80 |

| Velocity Blunt 35 | 30mm | 6061 | Sleeve | 590g | XC/AM | £80 |

| Velocity Dually | 39mm | 6061 | Sleeve | 675g | XC/AM/EN/+ | £104 |

| WTB Asym i29 | 29mm | WT69 | Welded | 583g | XC/AM/EN | £55 |

| WTB Asym i35 | 35mm | WT69 | Welded | 612g | XC/AM/EN/+ | £55 |

| WTB Kom i23 | 23mm | WT69 | Welded | 440g | XC/AM/EN | £63 |

| WTB Kom i25 | 25mm | WT69 | Welded | 465g | XC/AM/EN | £63 |

| WTB Scraper i40 | 40mm | WT69 | Welded | XC/AM/EN/+ | £86 | |

| WTB Scraper i45 | 45mm | WT69 | Welded | 712g | XC/AM/EN/+ | £86 |

MCFK’s 355g masterpiece

This is all before we got started on carbon rims, something that I feel is beyond the scope of what we are doing here and best to contact us for. Carbon is a superior material and allows for any of the above profiles to be improved upon, either allowing them to be made lighter, stiffer, stronger or all of the above. Nearly all the carbon rims we now offer are hookless for easier tubeless setup and better strength:weight. There is a full range of DCR carbon rims in the pipeline as well as some in stock already. Please contact for availability. We can offer carbon MTB rims from Alto Cycling, Knight Composites, ENVE, WR Compositi, 77 Composites and MCFK. Of that, ENVE generally sets the gold standard in terms of both premium pricing as well as function. MCFK offer the best in weight saving for a given profile. Knight and Alto are the comparative newcomers both with top end EPS based manufacturing, Toray carbon utilising the best manufacturing facilities in Taiwan (arguably the world). You may want to pair the Alto rims with Alto’s innovative hub design improving comfort and lateral stiffness.

Information on disc brake hubs can be found here.