Spokes and Nipples

A bicycle wheel can only be as good as its parts. A wheel is made of three main parts; hubs, rims and spokes. If any of these is poor then it will lead to a poor wheel. Even a stout rim will go out of true rapidly the wheel is built badly; and a good build requires good spokes. Spokes literally hold the whole item together.

Sapim define a spoke as, ‘being the link between the hub and the rim’. Spokes enable wheels to have remarkable strength with surprisingly little weight.

We use exclusively Sapim spokes. Sapim only make spokes and nipples. They offer a big range or products, allowing for an excellent option in any wheel. We have no concerns about the quality of DT Swiss spokes – there are a small number of subtle differences between them – however the Sapim range delivers a better solution for good value, high performance wheels that last for many years.

We offer almost the entire Sapim stainless spoke range. We do not offer their more basic, zinc range. Sapim have a permanent research centre so despite being established in 1908, they are still continuing to innovate and keep up with market developments. All Sapim spokes are made in either Belgium or France.

We have listed below (in order of popularity), product information on:

Butted Spokes

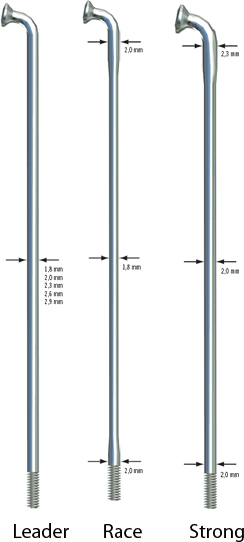

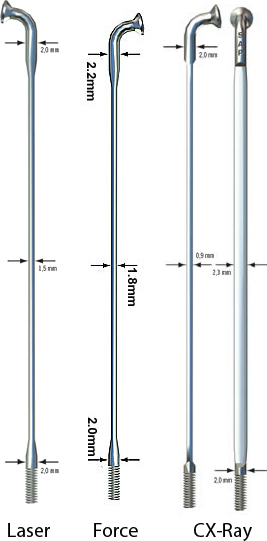

When an impact is made upon a wheel such as riding over a rough surface or hitting a pothole, the spoke needs to help absorb these irregularities. It is when a wheel receives these sudden forces that butted and aero (which in the Sapim range are also butted) spokes become important. The dimensions of a butted spoke differ from plain gauge because they are not a continuous thickness throughout. Sapim’s butted spokes use the SCFT-system (Sapim Cold Forging Technology). This allows the spoke to be stretched without causing any damage to its molecular structure and Sapim claim this increases the strength in the central portion by at least 48%. Butted spokes can flex and absorb impacts better than plain gauge because their central butting allows them to stretch. The extra material around the elbow and nipple allow strength to be retained in the areas that commonly fail. Finally the thinner central portion allows the butted spoke to be lighter than the plain gauge.

Sapim CX-Ray

The most famous aero spoke produced by Sapim is called the CX-ray. It is 2.0mm at the elbow, the centre section is oval and is 2.3mm deep but only 0.9mm wide. The CX-ray was developed from the Laser spoke. They have hammered it into an aero profile. The profile allows for compatibility with almost all hub types and standard nipples. One disadvantage of previous ‘bladed’ spokes is that they often required hub filing. This was not only tedious but also weakened the hub. Some hubs came pre-filed but this limits choices for builds, now bladed spokes have now fallen out of fashion in favour of aero spokes. The CX-rays are so strong that they are even rated as suitable for downhill racing. We stock CX-Rays in both J bend and Straight pull variations. We don’t recommend the use of straight pull hub design with a round spoke – if too much friction is present between the spoke and nipple and insufficient at the hub, the spoke will endlessly revolve rather than being able to be adjusted. Round straight pull spokes must have specially cut profiles at the head which dig into the hubs to prevent this. However, with an aero spoke this can be held steady and long term fine tuning is still possible.

Sapim also produce the CX-Sprint spoke. The CX-Sprint we only stock in black (unlike all the other spokes previously mentioned). Like the CX-Ray we carry it in J bend and Straight pull. The CX-Sprint is very similar to the CX-Ray but slightly heavier and slightly thicker in the central portion. The spoke was developed for those looking for a stiffer spoke than the CX-Ray. Most applications of the CX-Ray are alongside stiff rims and hubs, however sometimes particularly powerful riders appreciate greater stiffness especially in the rear wheel. For this reason, CX-Sprint spokes either throughout at the back or on the drive side rear will increase stiffness here. It does come with a comfort penalty as well as weight penalty and the spoke is not as durable as the CX-Ray, so it is only an advantage principally for those looking for maximum stiffness.

We do not offer Pillar spokes because we put a lifetime warranty on our builds and this requires us to use spokes which can rely on long term. However, one of the economies found by Pillar with their ‘aero’ spokes is that the spokes are simply a flat profile – like a ruler, rather than aero like a wing. It is a much more economical way of flattening a spoke and we would always rather use the higher end and far more elegant CX-Ray.

Sapim D-Light

The D-Light is a nice round spoke. The D-light spoke can be unpopular with wheelbuilders because it is the only spoke of the Sapim range which cannot be trimmed or cut/rolled from blanks with spoke machines. It is nevertheless a spoke we carry in a broad range of lengths because it is a far more carefully optimised spoke than the Laser and Race. It is a step up in sophistication and becomes a far better choice than the Laser for performance applications which are there to be used long term.

I like this spoke a lot because it emobodies good design and reaps the rewards in every area. It’s lighter than the Race, and yet the strength is as impressive in most scenarios. The elbow is still 2mm thick, but this section is cut short early on and the thinner 1.65mm section starts sooner than with most double butted spokes. No material is wasted; this 2mm section doesn’t need to be any longer for most applications. The same at the other end; the 2mm butting starts where the threads begin, rather than further down the spoke. This keeps the spoke light and comfortable.

Sapim Race

Sapim’s most common double butted spokes are called Race spokes. This is equivalent to DT Swiss’ Competition spokes. They are 2.0mm thick both ends and 1.8mm thick in the central section. This became over time the standard choice for most wheels, and are very popular with bike shops because of their versatility. They are often used as a replacement spoke when one has failed. They are good for MTB, standard touring, standard road use, any wheel that requires a solid and reliable spoke.

For a lot of riders, the D-Light is strong enough. Those looking for extra strength may find it in the Race, however there are even stronger options which can be combined with the Race to produce a nice hybrid system where the extra strength is provided where needed (the rear drive side or front disc side for example).

Sapim Force

The Sapim Force is a special spoke. Whereas the D-light is a lighter weight, lighter duty and more performance focused spoke than the Race, the Sapim Force in contrast goes the other way. The Force is no longer a double butted spoke but a triple butted spoke. It is 2mm at the threads to allow full compatibility with standard nipples. It is 1.8mm in the central portion like the Race and then 2.2mm thick at the elbow. Sapim realised that the weakest point on their spokes was the elbow rather than the threads, so re-inforcing this area provided greater strength/resilience. The thicker head leads to a tighter fit in the hub, and while the spoke is suitable for use with most durable hubs, it is not suitable for use with Royce hubs for example.

All of this makes the Force slightly heavier than the Race but a lot tougher and a lot more durable. A good option for rough gravel riders, MTB’ers and touring riders. It can be used in a hybrid system with a lighter spoke to save overall weight.

Sapim Strong

The Sapim Strong is, as the name suggests, capable of carrying very high loads. In reality it’s only one step up from the Leader spoke. It’s a single butted spoke, 2mm throughout except for its extra thick spoke elbow where it is 2.3mm. So it is like a Leader with an extra thick elbow. For this reason we can also cut these down to 70mm easily. They are stronger than the Leader but no more comfortable, and because of the thicker elnow, a little heavier. We’ve commonly combined the Strong spoke with Race spokes to make a hybrid wheel, with the Strong spokes on the rear drive side and Race spokes eslewhere, where the extra thick elbow isn’t needed and would just be added weight.

Plain Gauge Spokes

The plain gauge spoke is the basic spoke used in the vast majority of wheels across the world. Most wheelbuilders don’t choose them. There are two versions that Sapim makes; the Zinc spoke and the Leader spoke. The Zinc spoke is the most basic version and is quite simply a cheap spoke, which we do not offer. If you want a spoke which lasts and you want one which works well in conjunction with alloy nipples, a stainless spoke is required – especially in the UK where our weather conditions can be very harsh on components.

Sapim Leader

The Sapim Leader is the most basic spoke we sell. Leader spokes receive the same strengthening treatments as their butted spokes, which means they have a lot more strength than most competing versions. They are also still made from stainless steel. The main disadvantages of the Leader spoke over other Sapim spokes are weight, comfort and fatigue life. The Leader is still only really a basic spoke, best suited to economical wheelsets. They are available in a range of profiles so they can be applicable for builds which require unusually large spokes. They also offer a huge range of lengths which can be modified if necessary. We have a couple of spoke cutting/rolling machines which allow us to produce Leader spokes down to 70mm.

Sapim Nipples

Nipples are the little screw that hold the spoke into the rim on the wheel. While it may seem like there is an entirely straightforward selection for your wheels, there is quite a bit more detail to them than you might imagine. Quality nipples come in two major materials; either brass or aluminium alloy. There are also a few different designs, outside of the common slotted design.

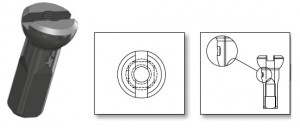

Double Square Or Slotted?

For the vast majority of our builds we use Sapim ‘double square’ nipples, which have numerous advantages over their more traditional slotted counterparts. They have longer threaded sections which means more threads on the spoke can engage, spreading the load better. They can be adjusted with a square driver as well as a conventional spoke key which reduces the chance of the colourful anodising and protective coating being damaged during building or truing. However the main advantage is the increased strength when compared to nipples of a slotted design – which can collapse in at the top if the spoke doesn’t reach the very top of the nipple. The double square nipples to not have a weak point like this and therefor are not vulnerable to the same types of failures sometimes seen with slotted nipples.

The new coating also means that these nipples require less lubrication – although we still recommend builders lubricate all nipples, with the exception of spokes under low tension – for example the on non drive side rear. They are squeal free during the build. They also retain the weight saving advantages over brass. Sapim are confident that their alloy nipples will actually out-last their brass versions as they held up better to salt water tests. Alloy nipples can also come in different colours if you wish; green, gold, purple, black, blue, red and silver.

SILS and Secure Lock Nipples

A few years ago now Sapim released a type of nipple called SILS, that contained Sapim’s Integrated Locking System. This system prevented spokes from loosening by deliberately imperfecting the thread in a certain way. They are only recommended for use with Sapim spokes and experience tells me that they do not work with DT Swiss for example. If you are planning to use them for a build, it is worth keeping an eye on the wind of the spoke. The increase friction can damage the spoke unless extra care is taken; this is a particular problem with the Laser spoke.

Nevertheless loosening is a problem worth trying to overcome. Even high end wheels can work loose leading to a potentially dangerous wheel. Different builders and manufacturers use different approaches to tackle this. Some use no lubricant at all during the build to maximise friction however this can cause damage to the components during the build and inhibits the high tensions required for a stiff wheel. It also can cause the spoke to seize up, preventing retruing. Others, like myself, use linseed oil as an organic substance that lubricates during the build but then acts like a mild threadlock afterwards. This is what I use on wheels that do not use locking nipples. You can use light thread locking compounds (like DT’s spoke freeze) in conjunction with other lubricants to retain some re-truing potential.

SILS nipples have recently been superceeded by secure lock nipples. The technology is similar but the nipple is slightly different. Previous SILS nipples became stiff when screwed further onto the spoke. These have tight spots and slack spots. Secure lock nipples can be identified from other nipples because of the depression on their side (not visible when built). Sapim say that lubrication is not required when using their alloy nipples, however I do still recommend it. It helps to prevent corrosion even further and helps to prevent wind up on builds. I also recommend the use of a Sapim or DT Swiss spoke key for use with all Sapim nipples, they are available through DCR for £17 and include free delivery (UK).

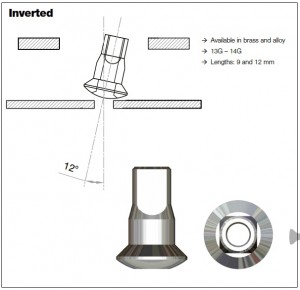

Secure lock nipples are also available in an upside down or inverted version. This does differ from turning an existing nipple upside down; it does not have a groove for a nipple driver. This is a key difference because if you were to use a regular slotted nipple upside down, that groove/slot will eat into your rim and cause unnecessary friction during the build. This can damage the nipple and the rim in the process. Inverted nipples have become more popular on carbon aero rims because the nipple interrupts the aerodynamics of the wheelset.

Another recent addition to the Sapim range is the HM nipple washer. This has been designed for use with non-eyeleted rims. Sapim maintain it is better to use a washer on a non-eyeleted rim, it provides a better surface to contact with, reduces friction, spreads the load better and helps to resist corrosion. However, it will add weight to your build and may require you to use longer spokes. The majority of our builds do not contain washers, but get in touch if you have queries.

Brass or aluminium?

Manufacturers of spokes such as Sapim, Wheelsmith, DT, Alpina all provide nipples with their spokes and in the overwhelming majority of cases you get some sort of brass, nickel coated nipples. These are cheap to manufacture and resist corrosion.

The main benefits of alloy nipples are weight saving. However, commonly these are made of the 2000 series aluminium which are comparatively weak. They can deform during the build, they can corrode with the elements and seize up to prevent re-truing. In contrast, Sapim’s alloy nipples are made out of 7075 aluminium which is stronger and more fatigue resistent. It also has a special anodized coating which resists corrosion, a problem that has plagued alloy nipples in the past.

So which material will I benefit from?

If brass is stronger, why go with anything else, you might ask? Well the question asked of every component on a bike is really is it strong enough? Brass nipples are roughly 3x heavier and across a 32h wheelset this adds up to 58g extra weight. If you’re thinking that doesn’t sound like much, imagine that a 58g weight saving was offered in a hub for no extra cost – most people would take it. It is a valuable upgrade because unlike most alloy nipples out there which are prone to corrosion, cracking or crumbling, Sapim alloy nipples do not come with any disadvantages and in your DCR wheels they will have a lifetime guarantee. Alloy nipples make sense as an upgrade if you are looking to add colour or performance to your wheelset.

Weight of 1 nickel coated brass nipple (18mm double square) – ~1.3g

Weight of 1 alloy nipple (18mm double square) – ~0.4g

Weight of 1 HM nipple washer – ~0.17g

Thickness of 1 HM nipple washer – ~0.7mm

If you were to add HM washers to a pair of 32 spoke wheels you will add approximately 11g to the wheelset. If you were to add them to a 20:24 laced wheelset you would add approximately 7.5g. When calculating spoke length if you are using HM washers, it is best to add 1.5mm to your effective rim diameter.

There is a lot more information available about choosing wheelsets, building wheels and selecting component parts as well as information on repairing wheels in Bicycle Wheelbuilding: The Manual an ebook which is available to purchase exclusively here:

https://dcrwheels.co.uk/product/bicycle-wheelbuilding-the-manual/